After all the deconstruction we did on the master bath in Phase 1, Phase 2, and Phase 3, it was finally time to start reconstructing it. This post is loaded with pictures, but there’s a lot of different things that went on to get the bathroom put back together.

First, I had to get rid of the old drain that I had left when cleaning out the old tile:

Of course, this meant going back under the house. That wasn’t too bad since the pipe I needed to cut was right beside the hole that I had cut in the floor:

I cut it off the pipe above the p-trap (so I didn’t have to replace that):

then installed a coupling and some pipe to get above the floor:

I left about 5″ sticking above the floor so there would be enough no matter what type of shower we decided to put in. The extra would be cut off when the shower floor is installed:

After that, I laid down the 1″ x 12″ pieces that I had originally cut out from the floor:

and nailed it down with the nail gun:

The exhaust from the air gun stirred up a bit of dust and the camera flash reflected it nicely so it looked like it was snowing inside:

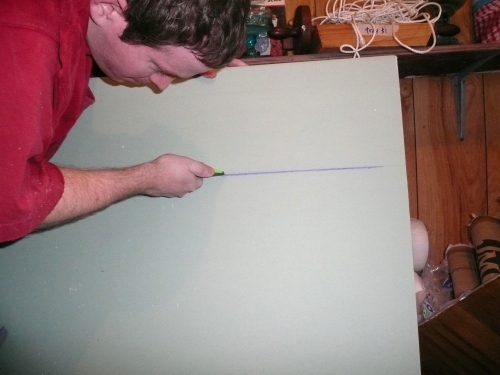

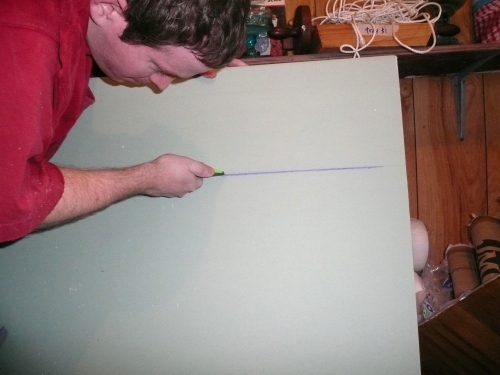

Next, I had to replace the plywood that I had taken out. The old plywood didn’t come out in one piece, so I had to cut a new one in an “L” shape. The best way to mark that out is to use a chalk line:

Here it is all cut out, including the hole for the drain pipe. Don’t want to forget that. I did have to adjust that hole a little after getting the plywood down, though:

Sometimes it can be hard to get a piece like this to fit just right, but this just dropped on in:

Okay, so maybe it was a little tight:

Well, maybe it was really tight:

I ended up have to trim a bit off to get it to fit. My original cut when I removed the old piece wasn’t completely straight so there was a little bump out in the way. After that, I screwed it down with deck screws that are rated for outside so they could handle any moisture being attracted from underneath the house since the old nails were half rusted through. I also screwed down a few spots of the plywood that I didn’t replace to keep it from squeaking. All done:

Yes, that is the same toilet paper roll I mentioned at the end of the Final Deconstruction post, but don’t worry, it is finally gone now.

Yay! No more going under the house for me!

The next thing I needed to do was install an exhaust fan. This bathroom is pretty small and there’s no window so the humidity levels will get pretty high. An exhaust fan will vent that and help to cut down on the possibilities of mold or things getting damaged from all the moisture. We decided to go with this Broan fan from Lowe’s:

We liked the fact that it wasn’t the standard big white square. It can also be found at Home Depot under the NuTone brand.

I decided to put it close to the edge of the existing sheetrock so I could install it from in the bathroom while I had the ceiling open rather than having to crawl in the insulation in the attic:

I set it up on top of the ceiling to mark the locations for the hole and for the screws that would hold it:

Since you can see the wires sticking out of this side, that means the vent is on the other side so I had to fasten the exhaust duct over there. It was a bit awkward, but was easier than trying to wire on the other side. Speaking of wire, that black wire on the right is the power wire from the switch. It was already in place for the light that was above the old shower so I didn’t have to install any of that.

Here’s the little saw I used to cut the hole. It’s handy, but kind of dull and a little bent so it still took some work:

I guessed I skipped taking anymore pictures until this one. Here’s the installed fan from below, minus the white reflector:

After all that, it was finally ready for drywall. I added some insulation back into the ceiling and a couple of areas on the wall first though:

The photographer changed for some of these next few pictures. Since I couldn’t take pictures of myself, Baz took most of these. Vanessa was at the store or something. Not bad for a 4yr old.

I originally had bought cement backer board to go up in the shower. At first, we planned on tiling it and the cement board is a better option to put on the walls rather than any type of drywall. This is in case any moisture works its way through any of the grout and mortar of the tile or even the tile itself.

Since we changed (I think we did that at least twice) and decided to go with a synthetic (which is not water permeable) for the shower, I took the cement board back to Lowe’s and got something referred to as green board (yes, it is typically green colored). More appropriately it’s called moisture resistant drywall and is just what it sounds like. It stands up to moisture better than regular drywall (although not as well as cement board) but installs just like drywall which means it’s lighter and the screws go in easier than the cement board. It’s also cheaper.

It’s typical that the ceiling goes up first:

I started out with my cordless, but had to switch to a corded drill for more power. Makes me think I need to buy a new drill. Good excuse anyway.

The pieces I needed for the side walls weren’t a full 4′ wide so I had to cut down the whole length. The best way I found is to have the sheetrock standing on its side so you can work with it:

Since I had to cut down the long side, out came the chalk line again. Then using a box knife, I cut down the line. Since the knife won’t go all the way through the sheetrock this is really more of a scoring:

And then I just bent it backwards for it to snap perfectly at the scored line and then cut through the paper on the other side:

Just like I had to do on the plywood, there’s usually some small adjustments that need to be made to get it to fit, but in goes the first wall:

One thing to keep in mind is the wall piece needs to go all the way up against the ceiling and not down on the floor. This will give some support for the ceiling for when it can’t be fastened close to the edge and it also makes the joint smaller and easier to mud.

Don’t forget to cut a hole for the shower fixtures:

The back wall was just about the right size so I didn’t need to do any cutting on the piece. Although, if you look, you can see that it left a little wider gap on the sides:

And finally, the joint compound to cover up all the joints and screws. Also, you can see the ceiling had already been textured when I took this:

One nice thing about a small shower is that it cuts down on the number of joints that need mudding since you don’t need more than one sheet per wall.

It’s finally somewhat put back together and ready for a shower, wall texture and paint. It’s about time!

Have you ever ended up writing more than you thought you would? When this post started out, I didn’t think it was going to be that wordy, but it ended up about average for us.